Automated Potted Plant Loader

Automated machine for loading potted plants into trays of various sizes and configurations.

"This year we will probably sample about 11.5 million samples. Each sample needs to be individually processed - mixed, sub sampled and tested. A lot of that process we have automated with the help of Motion Design.

They were a logic partner to work with, when we looked at this entirely manual process. How do we go about moving from a manual state to an automated state? Work with an organisation that has the specialist skills in equipment design, software design, artificial intelligence, machine vision; skills we don't have internally.

I don't believe we could have delivered the volume of milk sample testing we are doing now if we had not automated, so it has had a very large and positive impact on our operation." - Brent Wollaston, National Herd Testing Manager, LIC

Here’s a selection of automation and software projects we’ve delivered over the past 29 years, demonstrating our expertise in custom machine design, robotics, control systems, and software integration.

Automated machine for loading potted plants into trays of various sizes and configurations.

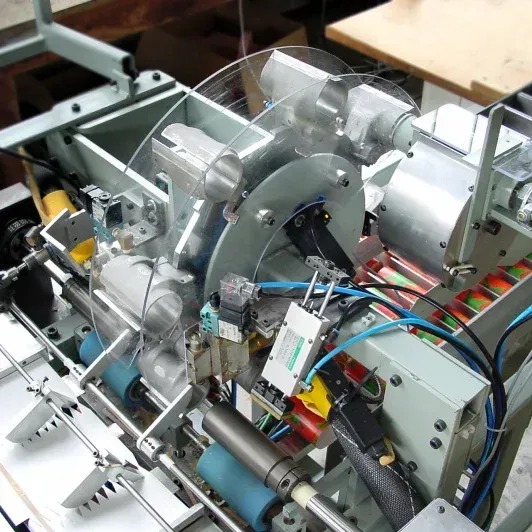

Custom machine to automatically fold a range of different diameter filter papers for use in their laboratory to free up valuable resources, reduce contamination, and ensure consistent filtration between samples.

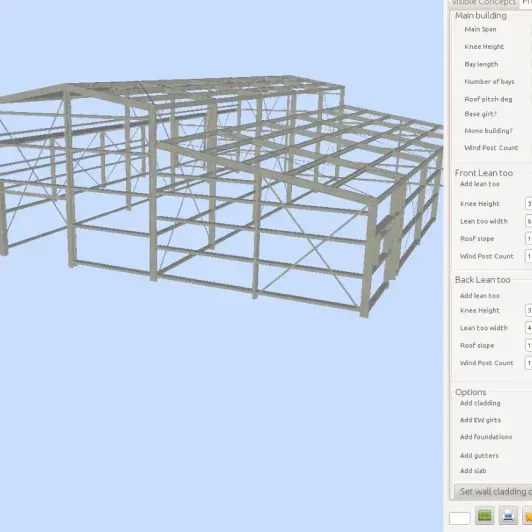

Franchisees can design large or small commercial/domestic sheds in 3D with external engineering rules and generate an accurate BOM and price LIVE direct to customers.

Control system and associated optimisation software used to create pre-cut (angle cut) roofing sheets to simplify the work of roofers.

A machine to automatically fold, into a cone, 110mm diameter filter papers for use in a NZ soil laboratory to free up valuable resources, reduce contamination, and ensure consistent filtration between samples.

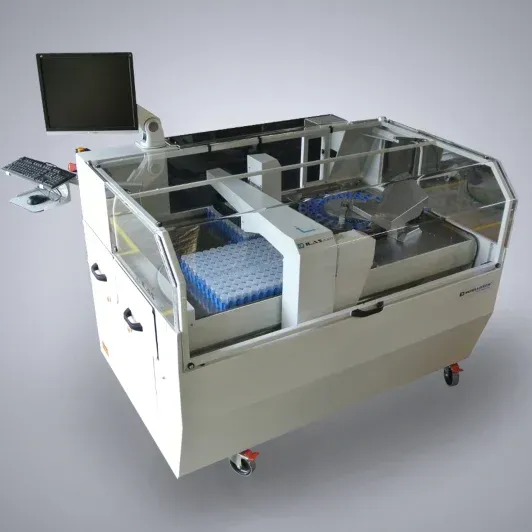

Custom automation to prepare milk samples and subsample them into smaller containers for testing. Includes weighing, mixing, measuring and identification processes and quality control.

A Motion Design milk sample preparation product that warms, mixes, decaps, identifies and presents to an analyser to gather milk component data.

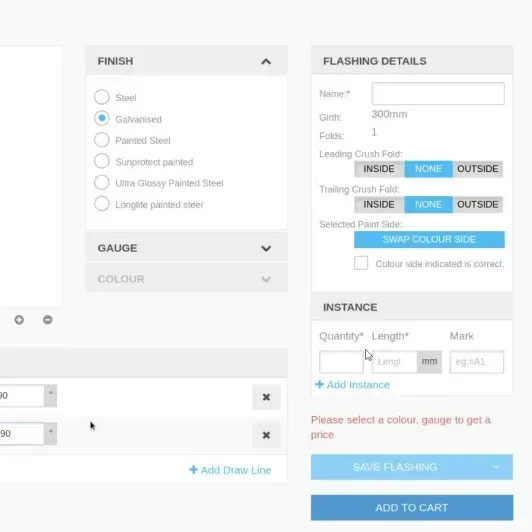

A cloud portal for a customer to design their own flashings and order them online. The sales order and the designs are automatically delivered to the production system for manufacture.

Research project involving a bespoke washdown robot for physically demanding beef brisket cutting and belly ripping processes.

Custom machine built for LIC’s Artificial Breeding division that counts out fresh semen straws into boxes for each order while inserting a coupon.

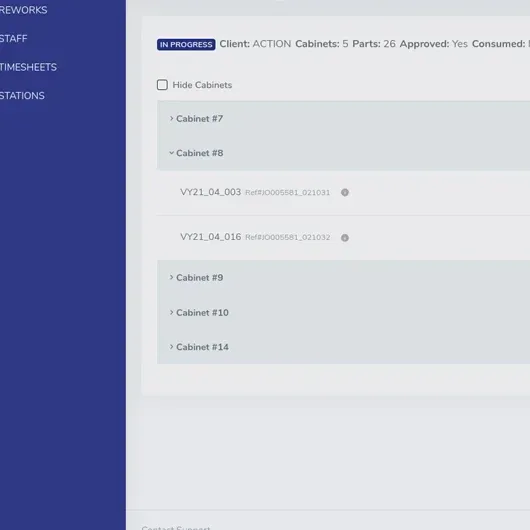

Factory software to give visibility and help track the progress and location of parts. Also integrates with an ERP system as well as design software.

Washdown robot designed to perform the tricky task of automated sheep Y-cutting, a world’s first in the late 1990s.

Bespoke robotic equipment to profile cut foam laminates into high-end body-boards.

Servo-based control system for high-speed cutting of extruded ice cream into ice-blocks with stick insertion.

Software and control system for a machine that produced high-end Christmas crackers.

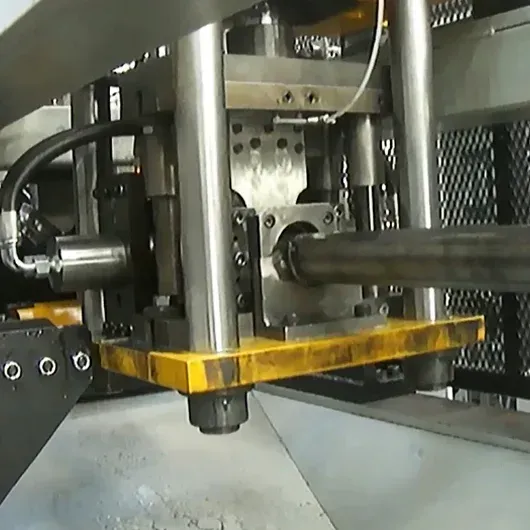

Servo control systems for press feeding and roofing tile coating systems.

Fun side project where some of the team created a flying machine based on a gannet, a famous local bird.

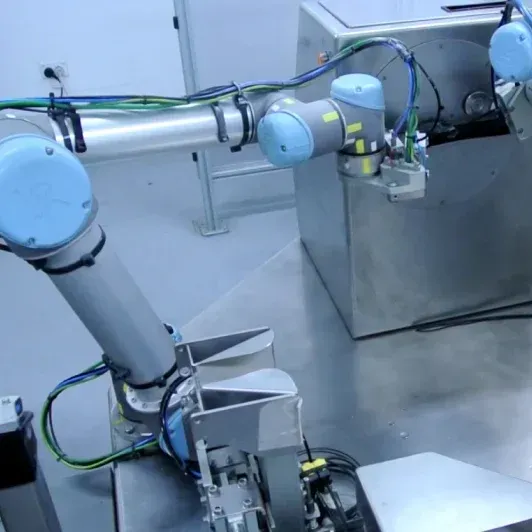

Bespoke SCARA robot system for matching up cow milk samples for mixing, pipetting and combining into a single proportional sample.

Custom designed system using a collaborative robot to pick-n-place various sized containers into boxes including cardboard inter-layers.

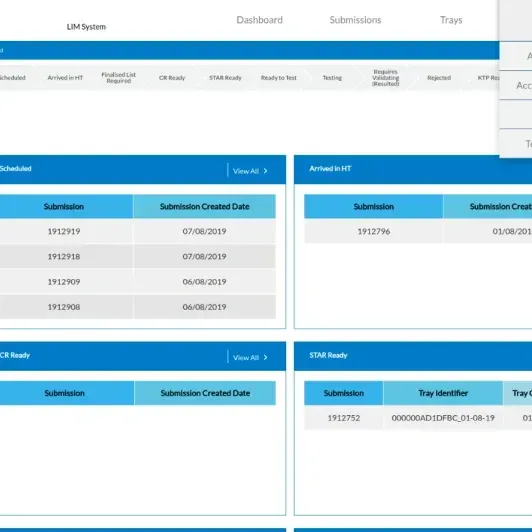

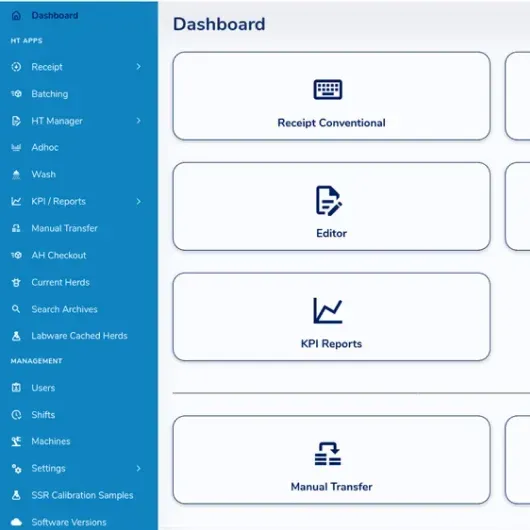

A custom built LIM system for LIC’s Animal Health division, with more features and the ability to handle higher volumes of samples than Labware was able to cope with.

A custom-built LIM server that holds and maintains all samples being processed through the laboratory. Modern web apps are provided for editing and reporting on herd data, machines and user performance.

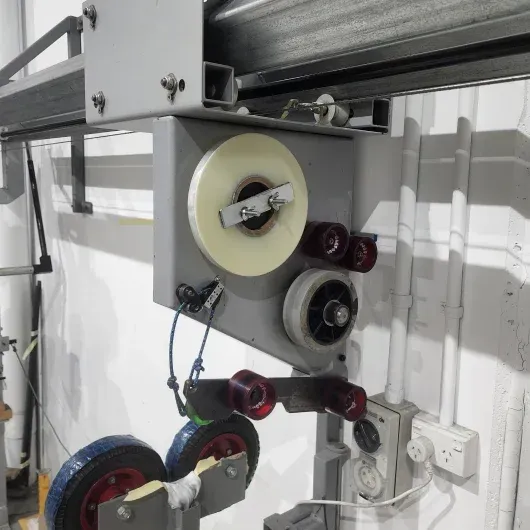

Robotic automation cell for hanking of wire looms, including a bespoke automated rubber banding machine.

A machine to automatically handle the multiple stages of dipping transformer coils into a varnish bath and baking them in an oven.

Robotic mixing and subsampling machine for honey analysis.

Complex control system for an advanced purlin mill. It manages servo controlled punch heads and automated raft settings.

Control System for high-speed machine making friction bolts for the mining industry

Control system for plastic wrapping for accurate tension and pitch control for carbon fibre sailing products.

Intelligent control system for running roll-forming equipment while managing workflows, material usage, operator logins, and managing and recording of waste.

Research project to develop a robotic system to wash sheep on a slaughter line.

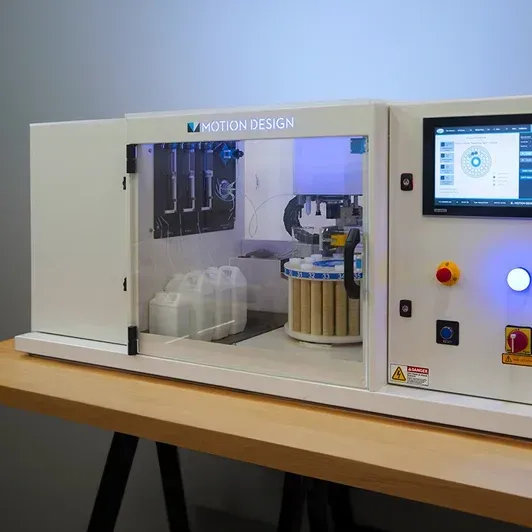

Machine to automatically dispense multiple liquids at pre-defined micro amounts into MARS Microwave digestion system turntables and vessels.

Development of a machine which feeds, cuts, presents and ultrasonically welds elastic straps to face masks.

Machine to feed, punch and place wire strips onto a running mask manufacturing line for moulding of the users nose to aid with sealing.

_XQfTL.webp)

_Z1SYk6k.webp)