Automated Potted Plant Loader

Automated machine for loading potted plants into trays of various sizes and configurations.

Mapper Weigher and Sub-Sampling Robot (SSR) – Bespoke Project

Delivering greater accuracy and repeatability with robotics

Automation software and laboratory automation can transform high volume and labour intensive processes into quicker, more accurate processes, like this solution for Livestock Improvement Corporation (LIC). See how our custom machines that utilised technology, including machine vision, delivered a range of business benefits such as greater repeatability and reduced operator error.

LIC uses a high throughput, labour intensive and repetitive 50-year-old manual process to collect and test individual cow milk samples. This process involves identifying the incoming samples by scanning barcodes (or for some herd type, by tray and position) and then proceeding one sample at a time through a range of manual tasks. These include picking up a flask, shaking the sample to mix it, taking the cap off and scanning the flask before finally putting the flask onto a scale and waiting for it to stabilise and take a reading.

This arduous process takes hours to complete, requires a high level of operator involvement and can result in inaccurate data due to the risk of operator error.”

The solution is machine automation: two custom machines that can be paired together but also work independently in case of a breakdown. The first machine is the Mapper Weigher. It creates a digital map of the tray samples with their weights. It involves trays of flasks entering a lifting system, which raises a row of flasks for barcode reading and weighing.

The second machine is called the Sub-Sampling Robot (SSR). The SSR sub-samples a similar volume of milk from a flask to a vial while tracking barcodes to match data. It handles a huge range of tasks simultaneously to achieve this, alongside automatically detecting errors.

These tasks include:

These custom machines:

The Mapper Weigher and SSR helps LIC:

“The machines had to achieve accuracy of weight measurement and subsampling volumes, consistent sample mixing, full traceability of samples, and no sample contamination. Because of these unique challenges, we weren’t able to use off-the-shelf automation and set about designing our own bespoke solution… For farmers this automation will result in even more accurate results to guide critical decision making on-farm.”

Brent Wollaston, LIC national herd testing manager “

Automated machine for loading potted plants into trays of various sizes and configurations.

Custom machine to automatically fold a range of different diameter filter papers for use in their laboratory to free up valuable resources, reduce contamination, and ensure consistent filtration between samples.

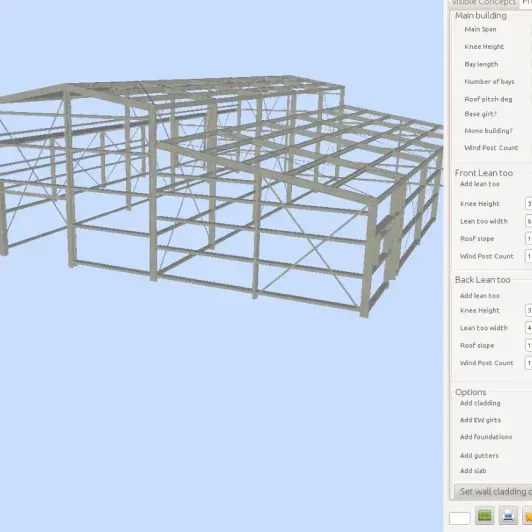

Franchisees can design large or small commercial/domestic sheds in 3D with external engineering rules and generate an accurate BOM and price LIVE direct to customers.

Control system and associated optimisation software used to create pre-cut (angle cut) roofing sheets to simplify the work of roofers.