Automated Potted Plant Loader

Automated machine for loading potted plants into trays of various sizes and configurations.

A smart laboratory automation solution, the ILAS3000 Waterbath Robot delivers intuitive, accurate, reliable data every time while providing a range of human benefits too.

Producing accurate data can be difficult to achieve using operators and basic equipment. Results can be too variable and unreliable. Robot integration, like the ILAS3000 Waterbath Robot, can solve these problems. That’s because it delivers consistent sample preparation for constant accuracy.

It also brings a wide range of benefits for humans, especially health and safety. Interactions with the Robot are through a screen, mouse and keyboard, keeping operators safely away from moving parts. By taking the heavy load of repetitive tasks, the risk of RSI is reduced.

IIoT reporting becomes simple with its strong software component that integrates with laboratory IT systems (LIMS) and enables thorough data.

The ILAS3000 Waterbath Robot is customisable to suit a range of sample vial types. It can be serviced remotely, allowing businesses all over the world to operate it trouble-free.

Reduce operator error and ensure accurate data thanks to consistent sample preparation with this laboratory automation solution.

Keep employees safe and minimise the risk of workplace injuries, including RSI, by automating manual tasks.

Make set up simple – the ILAS3000 Waterbath Robot integrates with laboratory IT systems (LIMS).

Businesses who:

Ensuring accurate, reliable data is key to certain businesses, like Livestock Improvement Corporation (LIC). Yet using operators and basic equipment is too variable and can cause unreliable data. We created a laboratory automation solution that eliminated their problems and has become adopted internationally. Find out more about the ILAS3000.

Milk samples require precise and consistent preparation procedures to achieve accurate and reliable test results. Attempting this with operators and basic equipment is too variable and can lead to unreliable data as LIC discovered. Following preparation, samples were placed in a rack and passed though the milk analyser, resulting in a variation in temperature between the first and last sample being analysed. In addition to a tedious and RSI-inducing task for operators, LIC lacked any comprehensive traceability of samples.

We created the ILAS3000 Waterbath Robot, a laboratory automation solution that removed problems around milk sample preparation. The ILAS3000 custom machine reduces operator involvement in the milk testing process by operating unattended for long shifts. The operator only needs to load and unload trays. Any interaction with the machine is through a screen, mouse and keyboard, allowing the operator to check errors and monitor progress.

To prepare the sample, a gantry system picks up the vial and moves it to a carousel in a water bath that’s temperature controlled to ensure perfect heating. The vial is then shaken, de-capped and scanned before being presented to the analyser. After analysis, the vial is returned to its tray of origin. The milk samples are tracked throughout the process using barcodes. The analyser data can then be paired with the correct sample.

The ILAS3000 has a strong software component and can integrate with laboratory IT systems (LIMS) and provide data for IIoT reporting. It can also be customised to suit a variety of sample vial types.

Numerous international dairy labs operate multiple ILAS3000s. Its reliability and ability to be serviced remotely means that the ILAS3000 is trouble free for operators and lab managers.”

This custom machine:

The ILAS3000 Waterbath Robot helps dairy labs:

“Since we’ve had the Waterbath Robot, there’s a definite improvement in quality, mainly around the consistency in how each sample is handled as opposed to the conveyors where individual operators used to handle the samples very differently.” - Karyn Lane, Sample Processing Manager

Automated machine for loading potted plants into trays of various sizes and configurations.

Custom machine to automatically fold a range of different diameter filter papers for use in their laboratory to free up valuable resources, reduce contamination, and ensure consistent filtration between samples.

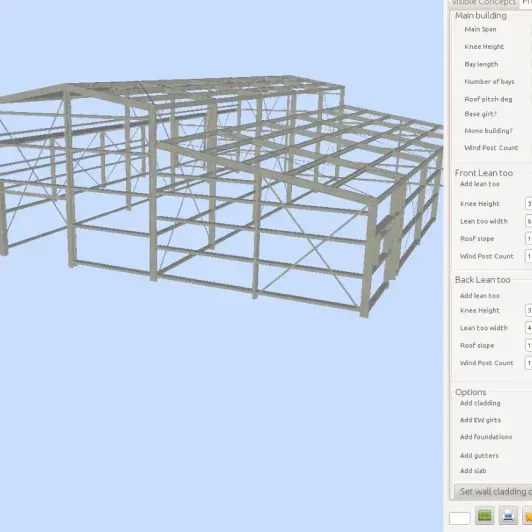

Franchisees can design large or small commercial/domestic sheds in 3D with external engineering rules and generate an accurate BOM and price LIVE direct to customers.

Control system and associated optimisation software used to create pre-cut (angle cut) roofing sheets to simplify the work of roofers.