Quality Assurance Checks

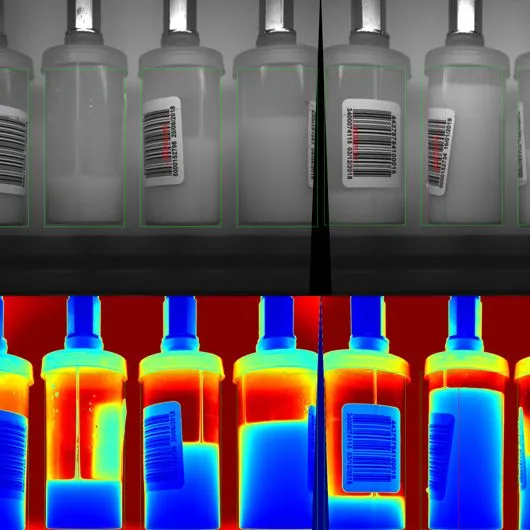

Check for defects, dimensional tolerance, product features or labels as part of automated quality assurance.

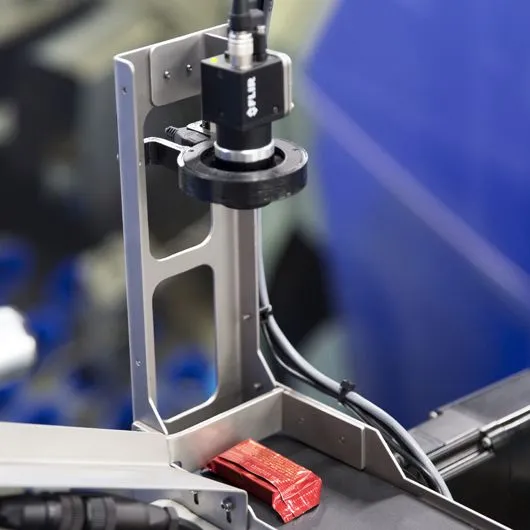

Motion Design can integrate machine vision systems into your operations using advanced industrial cameras. These smart solutions enhance production with automated quality assurance and quality control, enabling precise product identification, part recognition, and barcode or QR code scanning—ensuring accuracy and full traceability throughout your process.

Software is an integral part of machine vision and together with robotics or automation equipment, will make your process smarter and improve quality control and help drive better efficiencies and productivity.

Check for defects, dimensional tolerance, product features or labels as part of automated quality assurance.

Measure a product to determine what it is, even comparing it to drawings in a database.

Integrate a camera into your system so that a robot can be guided by the actual position of objects.

Developing systems that can recognize and differentiate colors for quality control and other applications.

Using machine vision to scan multiple barcodes and QR codes at once for inventory management and tracking.

Use machine vision to recognize and read text on objects and make decisions based on what is written.

Inky is an automation machine equipped with a vision system that detects and identifies steel parts, printing QR codes and part information directly onto them as they move along a conveyor. This enables their identification and tracking within the customers order system.